By Chander Chadha, Director of Marketing, Flash Storage Products, Marvell

AI is all about dichotomies. Distinct computing architectures and processors have been developed for training and inference workloads. In the past two years, scale-up and scale-out networks have emerged.

Soon, the same will happen in storage.

The AI infrastructure need is prompting storage companies to develop SSDs, controllers, NAND and other technologies fine-tuned to support GPUs—with an emphasis on higher IOPS (input/output operations per second) for AI inference—that will be fundamentally different from those for CPU-connected drives where latency and capacity are the bigger focus points. This drive bifurcation also likely won’t be the last; expect to also see drives optimized for training or inference.

As in other technology markets, the changes are being driven by the rapid growth of AI and the equally rapidly growing need to boost the performance, efficiency and TCO of AI infrastructure. The total amount of SSD capacity inside data centers is expected to double to approximately 2 zettabytes by 2028 with the growth primary fueled by AI.1 By that year, SSDs will account for 41% of the installed base of data center drives, up from 25% in 2023.1

Greater storage capacity, however, also potentially means more storage network complexity, latency, and storage management overhead. It also means potentially more power. In 2023, SSDs accounted for 4 terawatt hours of data center power, or around 25% of the 16 TWh consumed by storage. By 2028, SSDs are slated to account for 11TWh, or 50%, of storage’s expected total for the year.1 While storage represents less than five percent of total data power consumption, the total remains large and provides incentives for saving. Reducing storage power by even 1 TWh, or less than 10%, would save enough electricity to power 90,000 US homes for a year.2 Finding the precise balance between capacity, speed, power and cost will be critical for both AI data center operators and customers. Creating different categories of technologies becomes the first step toward optimizing products in a way that will be scalable.

By Winnie Wu, Senior Director Product Marketing at Marvell

Welcome to the beginning of row-scale computing.

At the 2025 OCP Global Summit, Marvell and Infraeo will showcase a breakthrough in high-speed interconnect technology — a 9-meter active electrical cable (AEC) capable of transmitting 800G across standard copper. The demonstration will take place in the Marvell booth #B1.

This latest innovation brings data center architecture one step closer to full row-scale AI system design, allowing copper connections that stretch across seven racks - that’s nearly the length of a standard 10-rack row. It builds on the prior achievement by Marvell of a 7-meter AEC demonstrated at OFC 2025, pushing high-speed copper technology even further beyond what was thought possible.

Pushing the Boundaries of Copper

Until now, copper connections in large-scale AI systems have been limited by reach. Traditional electrical cables lose signal quality as distance increases, restricting system architects to a few meters between servers or racks. The 9-meter AEC changes that equation.

By combining high-performance digital signal processing (DSP) with advanced noise reduction and signal integrity engineering, the new design extends copper’s effective range well beyond conventional limits, maintaining clean, low-latency data transfer over distances once thought achievable only with optical fiber.

By Annie Liao, Product Management Director, ODSP Marketing, Marvell

For over 20 years, PCIe, or Peripheral Component Interconnect Express, has been the dominant standard to connect processors, NICs, drives and other components within servers thanks to the low latency and high bandwidth of the protocol as well as the growing expertise around PCIe across the technology ecosystem. It will also play a leading role in defining the next generation of computing systems for AI through increases in performance and combining PCIe with optics.

Here’s why:

PCIe Transitions Are Accelerating

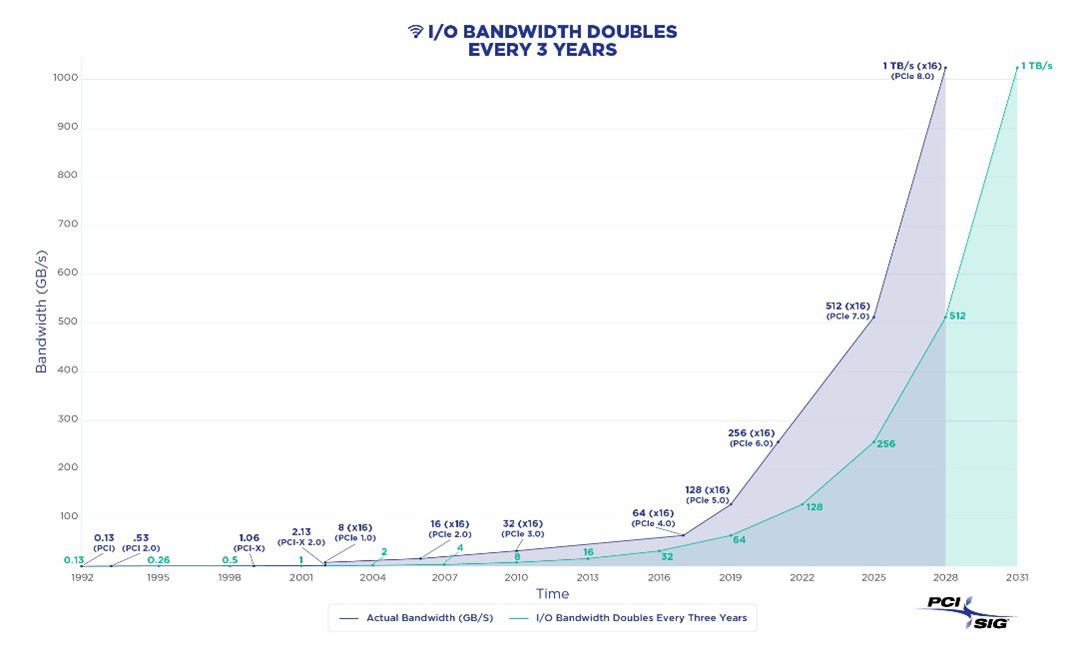

Seven years passed between the debut of PCIe Gen 3 (8 gigatransfers/second—GT/s) in 2010 and the release of PCIe Gen 4 (16 GT/sec) in 2017.1 Commercial adoption, meanwhile, took closer to a full decade2

Toward a terabit (per second): PCIe standards are being developed and adopted at a faster rate to keep up with the chip-to-chip interconnect speeds needed by system designers.

By Xi Wang, Senior Vice President and General Manager of Connectivity, Marvell

AI has been a huge catalyst for the adoption of connectivity in networks.

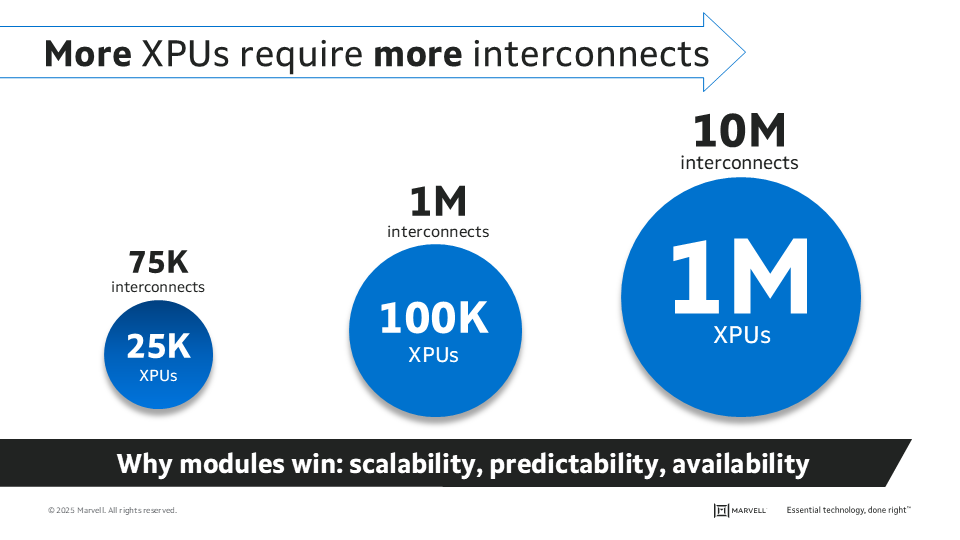

Already, operators are deploying AI data centers with over 200,000 GPUs—and they’re moving even faster towards 1 million XPUs. Driven by the increase in bandwidth and the growing size and number of clusters needed for AI applications, we are in a massive growth market for interconnect solutions. Accordingly, the optical interconnect global market has doubled since 2020 to nearly 20 billion dollars in 2025, and it is expected to double again by 2030, with an industry CAGR (Compound Annual Growth Rate) of about 18%.1

By Michael Kanellos, Head of Influencer Relations, Marvell

Chiplets—devices made up of smaller, specialized cores linked together to function like a unified device—have dramatically transformed semiconductors over the past decade. Here’s a quick overview of their history and where the design concept goes next.

1. Initially, they went by the name RAMP

In 2006, Dave Patterson, the storied professor of computer science at UC Berkeley, and his lab published a paper describing how semiconductors will shift from monolithic silicon to devices where different dies are connected and combined into a package that, to the rest of the system, acts like a single device.1

While the paper also coined the term chiplet, the Berkeley team preferred RAMP (Research Accelerator for Multiple Processors).

2. In Silicon Valley fashion, the early R&D took place in a garage

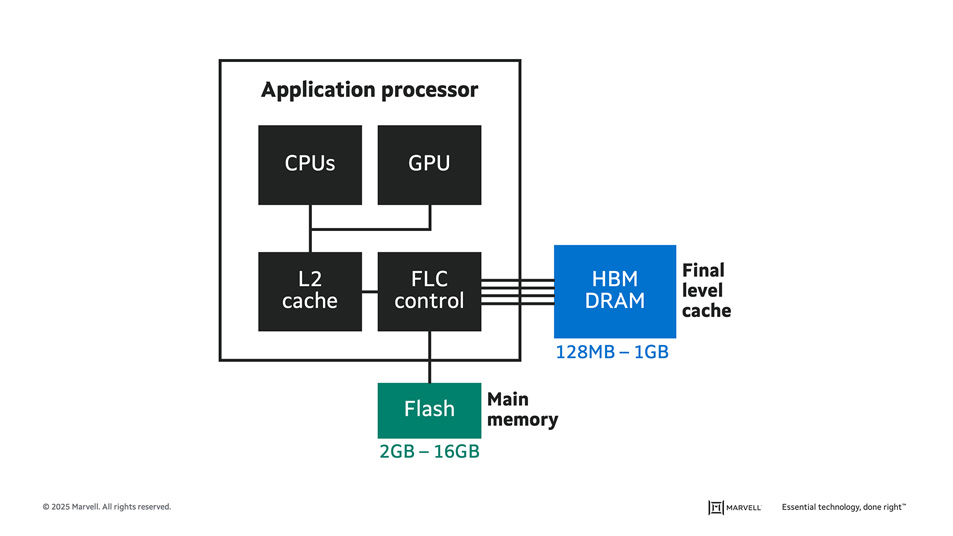

Marvell co-founder and former CEO Sehat Sutardja started experimenting with combining different chips into a unified package in the 2010s in his garage, according to journalist Junko Yoshida.2 In 2015, he unveiled the MoChi (Modular Chip) concept, often credited as the first commercial platform for chiplets, in a keynote at ISSCC in February 2015.3

The first products came out a few months later in October.

“The introduction of Marvell’s AP806 MoChi module is the first step in creating a new process that can change the way that the industry designs chips,” wrote Linley Gwennap in Microprocessor Report.4

An early MoChi concept combining CPUs, a GPU and a FLC (final level cache) controller for distributing data across flash and DRAM for optimizing power. Credit: Microprocessor Forum.