By Amir Bar-Niv, VP of Marketing, Automotive Business Unit, Marvell

When you hear people refer to cars as “data centers on wheels,” they’re usually thinking about how an individual experiences enhanced digital capabilities in a car, such as streaming media on-demand or new software-defined services for enhancing the driving experience.

But there’s an important implication lurking behind the statement. For cars to take on tasks that require data center-like versatility, they need to be built like data centers. Automakers in conjunction with hardware makers and software developers are going to have to develop a portfolio of highly specialized technologies that work together, based around similar architectural concepts, to deliver the capabilities needed for the software-defined vehicle while at the same time keeping power and cost to a minimum. It’s not an easy balancing act.

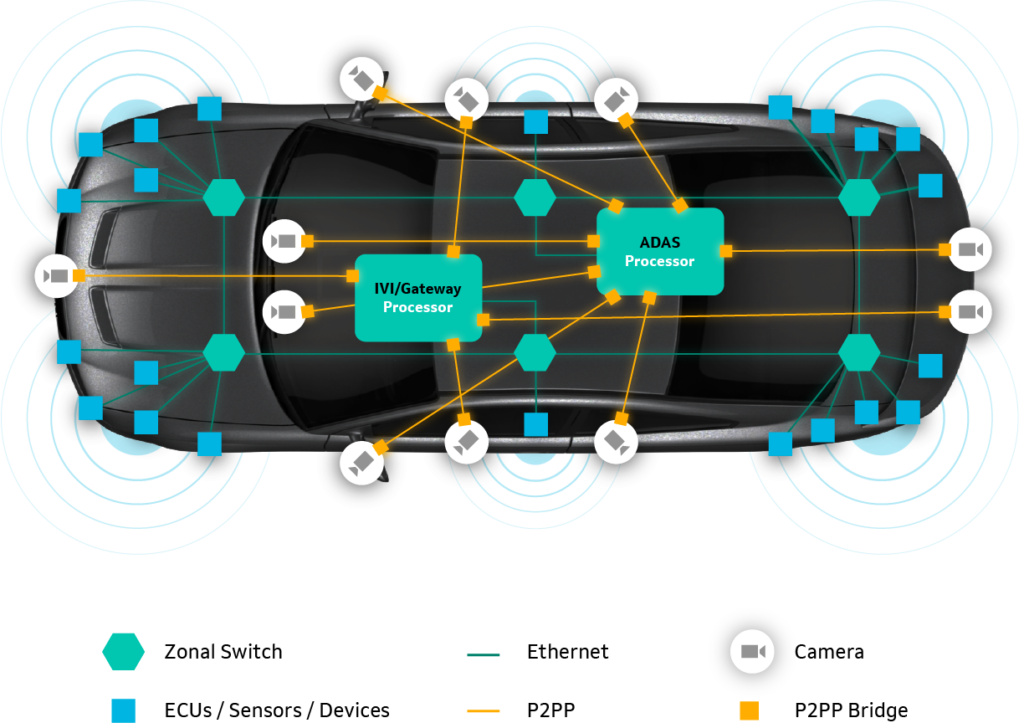

Which brings us to the emergence of a new category of products for the zonal architecture, specifically zonal and the associated automotive central Ethernet switches. Today’s car networks are built around domain localized networks: speakers, video screens and other infotainment devices link to the infotainment ECU, while powertrain and brakes are part of the body domain, and ADAS domain is based on the sensors and high-performance processors. Bandwidth and security can be form-fitted to the application.

By Willard Tu, Associate VP, Product Marketing – Automotive Compute, Marvell

Marvell is excited to announce that we’ve joined the automotive chiplet initiative coordinated by imec, a world-leading research and innovation hub in nanoelectronics and digital technologies. Imec has formed an informal ecosystem of leading companies from multiple automotive industry segments to address the challenge of bringing multi-chiplet compute modules to the automotive market.

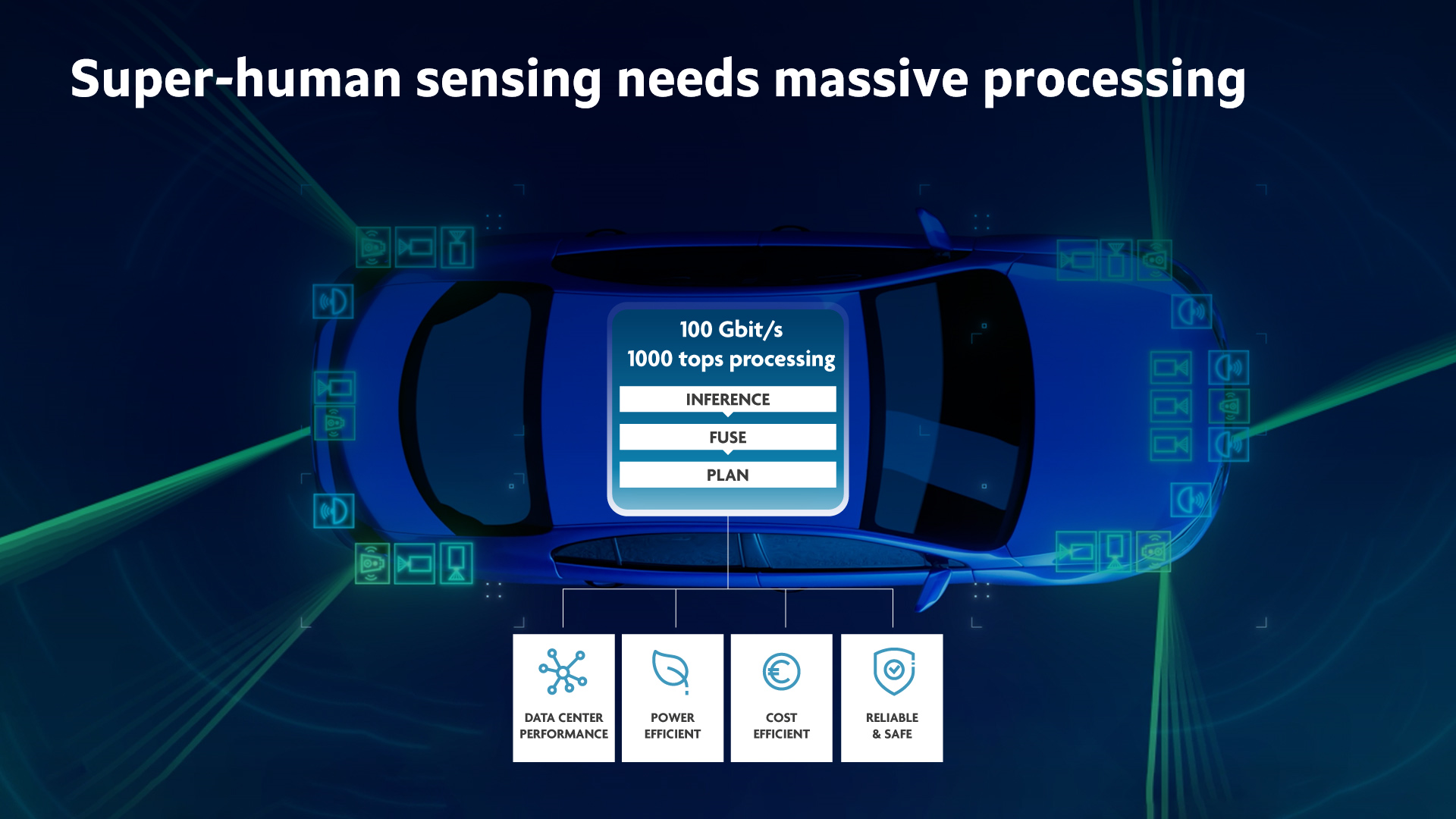

The goal of imec’s automotive chiplet initiative is to address the design challenges that arise from ever-increasing data movement, processing, storage and security requirements. These demands complicate the automotive manufacturers’ desire for scalable performance to address different vehicle classes, while reducing costs and development time and ensuring consistent quality, reliability and safety.

And these demands will be made even more intense by the coming era of super-human sensing. The fusion of data from multi-spectral cameras (visible and infrared), radar and LiDAR will enable “vision” beyond human capability. Such sensor fusion will be a critical requirement for safe autonomous driving.

By Amir Bar-Niv, VP of Marketing, Automotive Business Unit, Marvell and John Heinlein, Chief Marketing Officer, Sonatus and Simon Edelhaus, VP SW, Automotive Business Unit, Marvell

The software-defined vehicle (SDV) is one of the newest and most interesting megatrends in the automotive industry. As we discussed in a previous blog, the reason that this new architectural—and business—model will be successful is the advantages it offers to all stakeholders:

What is a software-defined vehicle? While there is no official definition, the term reflects the change in the way software is being used in vehicle design to enable flexibility and extensibility. To better understand the software-defined vehicle, it helps to first examine the current approach.

Today’s embedded control units (ECUs) that manage car functions do include software, however, the software in each ECU is often incompatible with and isolated from other modules. When updates are required, the vehicle owner must visit the dealer service center, which inconveniences the owner and is costly for the manufacturer.

By Willard Tu, Associate VP, Product Marketing – Automotive Compute, Marvell

I’m excited to share that Marvell is now a member of two leading automotive technology organizations: the Scalable Open Architecture for Embedded Edge (SOAFEE) and the Autoware Foundation. Marvell’s participation in these organizations’ initiatives demonstrates its continued focus and investment in the automotive market. The new memberships follow the company’s 2021 announcement of its Brightlane™ automotive portfolio, and reflect Marvell’s expanding automotive silicon initiative.

SOAFEE, founded by Arm, is an industry-led collaboration defined by automakers, semiconductor suppliers, open source and independent software vendors, and cloud technology leaders. The collaboration intends to deliver a cloud-native architecture enhanced for mixed-criticality automotive applications with corresponding open-source reference implementations to enable commercial and non-commercial offerings.

As a member of SOAFEE, Marvell will access the SOAFEE architecture standards to help streamline development from cloud to deployment at the vehicle. This will enable faster time to market for the Marvell Brightlane automotive portfolio.

By Amir Bar-Niv, VP of Marketing, Automotive Business Unit, Marvell and Mark Davis, Senior Director, Solutions Marketing, Marvell

In the blog, Back to the Future – Automotive network run at speed of 10Gbps, we discussed the benefits and advantages of zonal architecture and why OEMs are adopting it for their next-generation vehicles. One of the biggest advantages of zonal architecture is its ability to reduce the complexity, cost and weight of the cable harness. In another blog, Ethernet Camera Bridge for Software-Defined Vehicles, we discussed the software-defined vehicle, and how using Ethernet from end-to-end helps to make that vehicle a reality.

While in the near future most devices in the car will be connected through zonal switches, cameras are the exception. They will continue to connect to processors over point-to-point protocol (P2PP) links using proprietary networking protocols such as low-voltage differential signaling (LVDS), Maxim’s GMSL or TI’s FPD-Link.

Copyright © 2025 Marvell, All rights reserved.